|

Home - Carbon processing - Silver filtration

Technofilter Research-and-Manufacturing Enterprise Ltd is offering to businesses in the alcoholic industry an innovative technology for the production of vodkas using no carbon columns, “Silver Filtration®”.

The technology has been patented by Technofilter Research-and-Manufacturing Enterprise Ltd. Patent No 2 222 586, the method of “Silver Filtration” for treating water-alcohol mixtures and the cartridge filter.

Panta rhei (Everything flows, everything changes). Heracleitus Ephesus

Nowadays, life is changing rapidly before our eyes, technology is developing, life standards are rising. Unsurprisingly, approaches used in producing various products are also changing. At present any manager is aware of the fact that in order to keep the enterprise developing one should keep track of new technologies, adopt positive experience from colleagues, constantly seek to improve product quality. To be competitive, an enterprise needs new, effective technologies raising product quality and making the manufacturing process flexible, dynamic and hi-tech.

Technofilter Research-and-Manufacturing Enterprise has been working with distillery enterprises for more than 15 years. While solving filtration problems and communicating with process engineers and managers of distilleries, our specialists became interested in the problem of treatment of water-alcohol mixtures. The use of carbon columns, which involves passing the water-alcohol mixture through a 4-metre layer of active carbon (usually of the BAU-A grade), does not make it possible to promptly adapt to the constantly changing market situation. This is due to relatively slow processing rates of the water-alcohol mixture, high labour costs needed for operation of the columns and, most importantly, the impossibility of operating the columns in the batch mode (using the batch mode inevitably results in production of vodkas having a high content of aldehydes). Treatment of the water-alcohol mixture in a suspended carbon layer and the use of the Poltovchanka system make possible the batch mode operation, but require significant expenses on downstream filtration and, what is more, preclude flexible control over the contact time between the water-alcohol mixture and carbon.

Technofilter Ltd has developed a fundamentally new approach to treatment of water-alcohol mixtures for use by vodka producers.

The old classic method is the dynamic method of filtering the water-alcohol mixture through a stationary layer of carbon that has been found to be the most effective one among existing methods of treating the water-alcohol mixture. In the new method, carbon is acting not as the sorbent, but as the catalyst of redox reactions that in effect shape the taste and flavour of vodka.

Advantages «Silver Filtration®» Advantages of the Silver Filtration system: Advantages «Silver Filtration®» Advantages of the Silver Filtration system:

- compact size;

- highly effective treatment of vodka with active carbon (no less than 10 dal/hour per 1 kg of carbon);

- large throughput;

- easy and prompt replacement of elements, if necessary;

- minimal costs of test filtration due to high hardness of carbon;

- no aldehydes are accumulated when the process of treatment of water-alcohol mixtures is stopped, because both the amount of active carbon and the volume of the water-alcohol mixture coming into contact with it are greatly reduced in such cases;

- the possibility of:

- batch operation of the equipment,

- nonshift operation of the enterprise,

- flexible variation of the production rate (decreasing or increasing the production rate depending on demand).

Set of components

The Silver Filtration system (USF) is mounted on a frame and consists of:

- pumping unit (incorporating an explosion-proof pump);

- prefiltration unit (filter holder made of 12Kh18N10T stainless steel having an inspection window, accommodating various numbers of filter elements) for protection of carbon elements of the main stage from mechanical contaminants;

- carbon filtration unit (filter holder made of 12Kh18N10T stainless steel having an inspection window, accommodating various numbers of filter elements);

- manifold piping, stop valves, flowmeter;

- control console having automatic switch and frequency converter.

With the Silver Filtration technology, more effective use of production area is possible. There is no need to build a many-storied workshop, use pressure tanks and sand filters.

Quite recently producers of vodka believed that the technology only had marketing advantages, since it evoked positive associations with silver in Russian consumers. However, processing advantages of the technology were also revealed in due course, that resulted in adoption of Silver Filtration by more than 200 enterprises in 21 countries, including Russia. Silver Filtration is the main method used for processing water-alcohol mixtures in production of the following grades of vodka: Zelyonaya Marka, Zhuravli, Marusya, Pyat Ozyor, Flagman, Mlechny Put, Khortitsa, Belaya Beryozka, etc.

A prerequisite for development of the new method was the discovery of the fact that effectiveness of active carbon is increased when a small amount of colloidally dispersed silver is applied on its surface. The authors (A.S.Yegorov, N.Ya.Savchenko and G.S.Tomashevich in: P.Ya.Bachurin et al. “Technologies of alcoholic beverage production”) believe that the additional effect results from electrochemical potential difference that arises between carbon and silver and promotes redox reactions and reactions of esterification and saponification in the presence of oxygen.

Silver is known to be an active catalyst. Silver catalyzes not only the reaction of oxidation of alcohol into aldehyde but also subsequent reactions of oxidation into acetic acid and the reaction of formation of esters.

We have tested modern active carbons impregnated with silver. Carbons having various silver concentrations (0.04 to 4%), particle size profiles and origins were tested. Preference was given to granulated active carbons produced from coconut shells having surface silver concentrations of 0.4 to 0.5%. These carbons feature high hardness (>97%) and large specific surface areas (>1000 m2/g).

The tests have confirmed that the processing rate of water-alcohol mixtures is increased considerably. It became possible to reduce the amount of carbon used, i.e. to accomplish the transition from quantity to quality by taking advantage of new capabilities of carbon rather than its large weight in conducting chemical processes.

It was just this design of the filter element and the use of silver-containing carbon in production of vodka that was patented by Technofilter Ltd as “the method of “Silver Filtration” for treatment of water-alcohol mixtures used in production of vodka and the cartridge filter” (patent No 2222586 of 19.06.2002). It was just this design of the filter element and the use of silver-containing carbon in production of vodka that was patented by Technofilter Ltd as “the method of “Silver Filtration” for treatment of water-alcohol mixtures used in production of vodka and the cartridge filter” (patent No 2222586 of 19.06.2002).

The weight of carbon in the standard 250 mm high EPSF.UAg0.4 element (carbon “minicolumn”) ranges from 300 to 330 g, the content of silver is 0.4%. The filter elements are thermally welded together into candles 500, 750 or 1000 mm high and installed into the filter holder that can accommodate 3 to 24 candles depending on the required production rate.

Like classical carbon columns, the “minicolumns” should be operated in conformance with certain filtration modes. To this end, a standard range of Silver Filtration systems (USF) having processing rates of 40 to 1000 dal/hour has been developed and certified by Technofilter specialists. The systems are adapted to any production conditions, enable monitoring of the filtration process and, if necessary, its flexible modification.

Investigations carried out in association with All-Russian Research Institute of Food Biotechnologies (VNIIPBT) on an experimental-industrial scale in the workshops of VladAlko Open-End JSC (Vladimir), Pervy Kupazhny Zavod Ltd (Tula), SPI-RVVK Open-End JSC (Kaliningrad) and Alkon Open-End JSC (Velikiy Novgorod) have shown that a new method of vodka production was really developed. As a result of the tests, the Silver Filtration technology was included into the “Process regulations for production of vodkas and alcoholic beverages” (Amendment No 1 to PTR10-12292-99 of 07.11.2005, paragraph 8.5.9.).

Silver Filtration effectively accomplishes volume structurization of water-alcohol mixtures, making it possible to produce vodka that is not inferior in quality to vodka produced using carbon columns loaded with BAU-A carbon. In addition, the problems characteristic of classical carbon columns are solved, including the problem of aldehyde accumulation after stoppages in the process of treatment of water-alcohol mixtures, because the volume of the water-alcohol mixture contacting with carbon is drastically reduced in such cases.

New possibilities, methods and even proprietary secrets have emerged in the vodka production technology. Handling the product and controlling its quality has become more convenient. For example, by changing the processing rate of the water-alcohol mixture it is possible to produce vodkas differing in organoleptic characteristics depending on consumers’ tastes. Enterprises having small production volumes can now operate in the batch mode, because it is now possible at any time to stop the process and to resume it, when needed, without any losses of time or expensive raw materials. It is also possible to produce the required amount of the water-alcohol mixture containing additional components within one shift, and then allow time for it to assimilate and “have a rest”.

The process engineer now has a tool enabling him to implement objectives assigned to him, unveil the best properties of his product and produce a beverage in conformance with various tastes of consumers. By changing processing rates, it is possible to vary the softness of vodka, making it either very soft, with a delicate flavour, or more poignant, heating, for those who “like it hot”. It became possible to produce vodka from small batches of water-alcohol mixtures having special formulations, e.g. those purified by milk, while almost avoiding any losses.

Major producers of vodka point out other advantages of the Silver Filtration technology:

1. Compactness. The system occupies less working area due to its compact size (as compared to classical carbon columns) – one Silver Filtration system having the processing rate of 500 dal/hour (1430´970´1920 mm in size) replaces 10 carbon columns. In addition, pressure tanks are no longer needed.

2. Ease of maintenance. With the Silver Filtration systems, you no longer need to unload tons of carbon from carbon columns and fill them with fresh carbon (some large-size enterprises have up to 90 carbon columns!!!), spending human resources and, what is most important, time on this operation and subsequent cleaning of the production areas. It is no longer needed to bring the column into the normal mode, losing expensive raw materials as irreparable waste and, again, time. It is only necessary to replace filter elements.

Processing of water-alcohol mixtures using the Silver Filtration technology is also used in Ruchei continuous mode systems. These systems incorporate water-alcohol mixture processing units provided with filter holders for 24 1000 mm high EPSF.UAg0.4 elements. Ruchei systems use a modular design, making it possible to increase the production rate by increasing the number of modules. Water-alcohol mixture tanks are no longer needed, because the systems include modules for preparation of water-alcohol mixtures having preselected alcoholic content, in which proprietary injection units are used as mixers. Due to compactness of the whole system, including the water-alcohol mixture preparation unit and water-alcohol mixture processing modules incorporating EPSF.UAg0.4 elements, the vodka production process occupies an exceptionally small production area.

But the main advantage of Silver Filtration, common to all producers, is improved quality and organoleptic properties of the product, confirmed by numerous awards received at exhibitions and special tasting events.

It should be pointed out that our customers regard Silver Filtration not as a publicity ploy, but as an advanced technology helping in production of high quality products and making it possible not only to survive in a close competitive struggle, but also to consolidate one’s positions in the vodka market.

Apart from water-alcohol mixture processing, Silver Filtration can also be used for aftertreatment of vodka (“Process regulations for production of vodkas and alcoholic beverages” (Amendment No 1 to PTR10-12292-99 of 07.11.2005, paragraph 8.5.10. Test filtration of vodkas). This possibility is used in two cases:

1. A distillery decides to retain the dynamic method of treatment of the water-alcohol mixture (through carbon columns) and to use the Silver Filtration system for additional treatment.

2. An enterprise uses the Silver Filtration system instead of carbon columns but wishes to improve organoleptic properties of the product by adding one more filtration stage.

In both cases, the system used for aftertreatment can be diverted to treatment of the water-alcohol mixture in the cases when it is needed to promptly increase the production rate.

In addition to convenience and good qualitative properties of the product, a major advantage of Silver Filtration is the large throughput of filter elements.

The throughput of one 250 mm high EPSF.UAg0.4 element is 3,500 to 5,000 dal when used for treatment of the water-alcohol mixture and 7,000 to 10,000 dal when used for aftertreatment of vodka.

For example, the average throughput of the standard set of columns (24 1000 mm high elements or 96 minicolumns) is up to 500,000 dal in the case of 500 dal/hour flow rate.

The recommended flow rate for one 250 mm high element in the aftertreatment mode is 8 to 15 dal/hour. If maximum production rate of 1000 dal/hour is used, the throughput of the set reaches 1,000,000 dal.

It can be calculated that the cost of producing one 0.5 litre bottle using Silver Filtration is only 1 to 1.5 Kopecks.

Silver Filtration systems are successfully used by more than 200 distilleries in Russia, Ukraine, Belarus, Kazakhstan, Kyrgyzia, Georgia, Latvia, Lithuania, Estonia, Croatia and Mongolia.

Here is an incomplete list of distilleries using Silver Filtration: Veda Closed-End JSC, Topaz alcoholic beverage company Ltd (“Green Mark” vodka), “Pervy kupazhny zavod” Ltd (GK Russky Alkogol), Open-End JSC “Moskovsky Zavod Kristall”, Kristall Ltd (Ulyanovsk), Kristall Open-End company (Kaluga), Stolichny trest Closed-End company (Moscow), Tatspirtprom Association, enterprises of Sinergia Group, Khortitsa and Nemiroff (Ukraine) and many others.

Silver Filtration® systems are easy to maintain and the technology is adopted without any problems which improves operating reliability.

“Analogs” of Silver Filtration have already emerged. This not only violates the rights of Technofilter Research-and-Manufacturing Enterprise Ltd as a patent holder, but also compromises the regulated Silver Filtration technology itself, because the design of the filter element is not observed and less effective types of carbon are used. Besides, to achieve a good result, it is very important to observe filtration modes that are special to each distillery.

! Beware of counterfeits!

Characteristics of carbon minicolumns (elements)

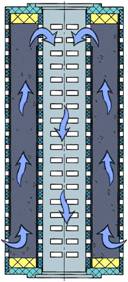

EPSF.UAg0.4 filter element is a carbon minicolumn containing silver-containing carbon loaded between the inner and outer shells, featuring longitudinal flow pattern.

These carbons feature high hardness (>97%) and large surface area (1000 m2/g). The technique used to impregnate the carbons with silver precludes migration of silver into the filtrate.

A standard basic EPSF.UAg0.4 filter element (minicolumn) having the height of 250 mm, outer diameter of 70 mm and inner diameter of 26 mm holds about 330 g of active carbon having the density of about 0.5 g/cm3. The special patented design of the filter element takes into account the ability of carbons to swell in the course of operation and precludes the possibility of “channelling” even at high filtration rates.

500, 750 and 1000 mm high filter elements can be produced on the basis of the basic filter element.

Depending on the required water-alcohol mixture processing rate, the number and height of filter elements as well as the grade of the filter holder or USF filtration system are selected.

The rate of water-alcohol mixture filtration through one 250 mm high minicolumn (element) is 3 to 7 dal/hour.

The filtration rate is monitored using a rotameter or flowmeter of the water-alcohol mixture and is set subject to obligatory beneficial effect of the treatment as detected by tasting assessment.

The difference in tasting assessment between vodka and the water-alcohol mixture should be no less than 0.2 points, the difference in oxidizability, no less than 1.5 min for Extra alcohol and 0 to 1.5 min for Lux alcohol. If no improvement in organoleptic properties is detected, the filtration rate should be reduced. If the tasting assessment of the water-alcohol mixture is not improved by the effect of carbon at the reduced filtration rate, the filter elements should be replaced.

Test filtration of vodkas

EPSF.UAg0.4 minicolumns (elements) incorporating silver-impregnated cocoa carbon can be used for additional treatment of vodkas.

Vodka treated in a carbon column or by any other regulated method is passed through the USF filtration system (TU 5131-009-10471723-2004) consisting of the pumping unit, the rotameter and stop valves and provided with EPSF.UAg0.4 filter elements and is then delivered to the filtered vodka collector or conditioning tank.

The resultant vodkas feature not only improved transparency (shine), but also improved organoleptic characteristics. Vodka filtration rates through one 250 mm high minicolumn (element) are 8 to 15 dal/hour. The filtration rate is monitored using a rotameter or flowmeter of the water-alcohol mixture and is set subject to obligatory beneficial effect of the treatment as detected by tasting assessment.

The throughput of one 250 mm high EPSF.UAg0.4 filter element in terms of vodka is 7,000 to 10,000 dal and depends on the quality of the original vodka.

Modifications of the system

|

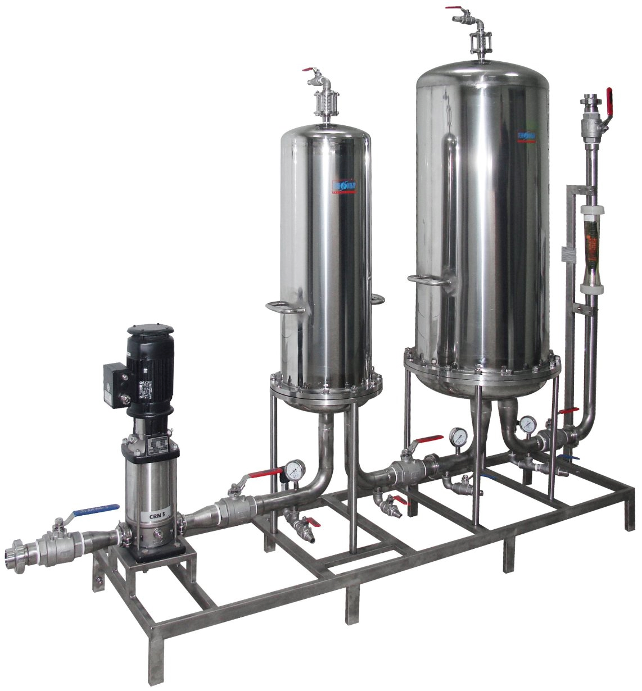

Silver Filtration system (USF) having production rate of 100 to 150 dal/hour when used for treatment of the water-alcohol mixture and 200 to 300 dal/hour when used for additional treatment of vodka

1 stage, prefilter (used instead of the sand filter)

2 stage, carbon treatment (Silver Filtration) |

|

Silver Filtration system (USF) having production rate of 200 to 300 dal/hour when used for treatment of the water-alcohol mixture and 400 to 600 dal/hour when used for additional treatment of vodka

1 stage, prefilter (used instead of the sand filter)

2 stage, carbon treatment (Silver Filtration) |

|

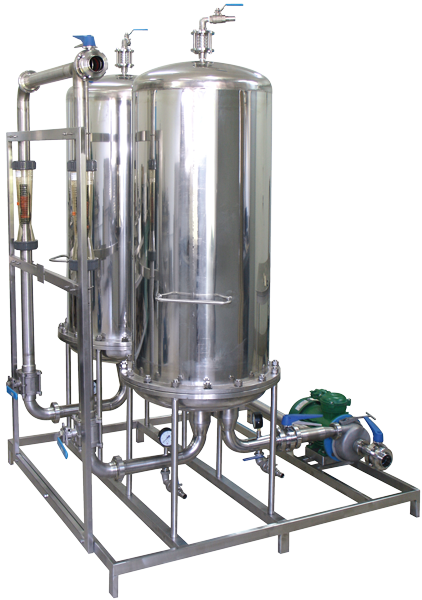

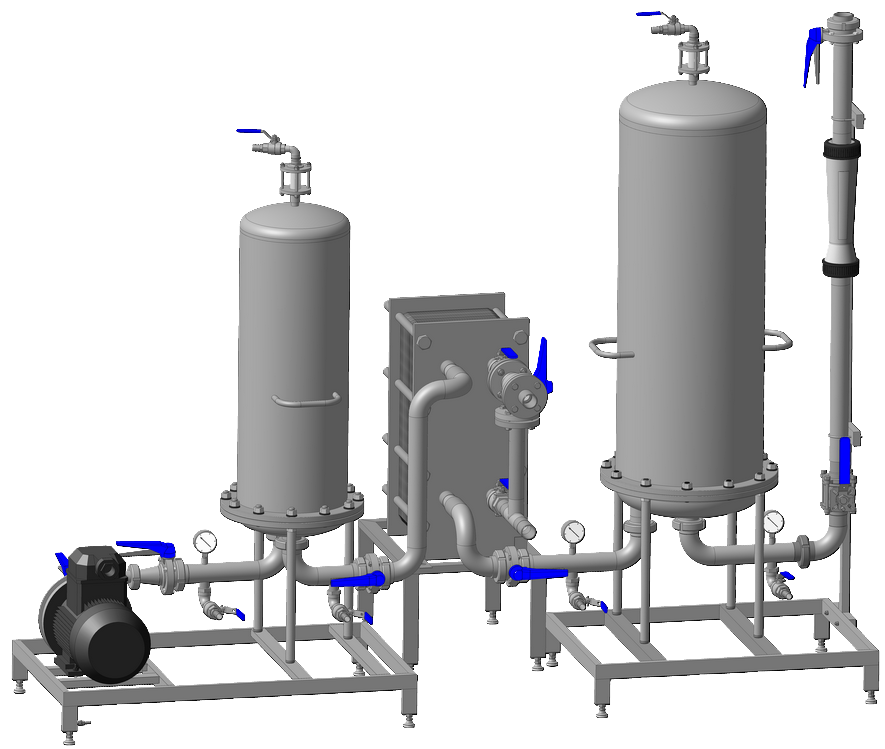

Silver Filtration system (USF) having production rate of 300 to 500 dal/hour when used for treatment of the water-alcohol mixture and 800 to 1000 dal/hour when used for additional treatment of vodka

1 stage, prefilter (used instead of the sand filter)

2 stage, carbon treatment (Silver Filtration) |

|

Silver Filtration system (USF) having production rate of up to 800 dal/hour when used for treatment of the water-alcohol mixture and up to 1600 dal/hour when used for additional treatment of vodka

1 stage, carbon treatment (Silver Filtration), two filter holders operating in parallel |

|

Silver Filtration system (USF) having production rate of of up to 800 dal/hour when used for treatment of the water-alcohol mixture and of up to 1600 dal/hour when used for additional treatment of vodka

1 stage, carbon treatment (Silver Filtration), two filter holders operating in parallel |

|

Silver Filtration system (USF) having production rate of up to 1200 dal/hour when used for treatment of the water-alcohol mixture and of up to 2400 dal/hour when used for additional treatment of vodka

1 stage, prefilter (used instead of the sand filter)

2 stage, carbon treatment (Silver Filtration), three filter holders operating in parallel |

|

Silver & Platinum Filtration System having production rate of 300-500 dal/hour when used for treatment of the water-alcohol mixture and 800-1000 dal/hour when used for additional treatment of vodka

1 stage, prefilter (used instead of the sand filter)

2 stage, carbon treatment (Silver Filtration)

3 stage, carbon treatment (Platinum Filtration having production rate of 450 dal/hour) |

|

Silver Filtration & bitter taste removal system having production rate of 300-500 dal/hour when used for treatment of the water-alcohol mixture and 800-1000 dal/hour when used for additional treatment of vodka

1 stage, sorptive filter for removal of bitter stuff (see section "New developments. Alcohol conditioning")

2 stage, carbon treatment (Silver Filtration) |

|

Silver Filtration system (USF) with the possibility of cooling

1 stage, prefilter (used instead of the sand filter)

2 stage, carbon treatment (Silver Filtration) |

|